-

Kenchic manages a fully integrated poultry operation, beginning with their hatcheries and extending through to their farms, culminating in a state-of-the-art, halal-certified meat processing facility.

-

Kenchic provides chicken items to prominent companies such as KFC, along with various supermarkets, eateries, and homes throughout Kenya.

-

The firm breeds its chickens under managed circumstances and avoids outsourcing to maintain rigorous food safety and animal welfare protocols, such as providing pesticide-free feed and ensuring disease-free settings.

Elijah Ntongai, working as a journalist for .co.ke, boasts more than four years of expertise in financial, business, and technology research and reporting. He offers valuable perspectives on both Kenyan and international developments.

Have you ever thought about the origin of the chicken on your plate, be it when it’s served piping hot at your favorite fast-food spot or packaged nicely in a grocery store freezer section?

Concerns about food safety and traceability have been increasing, especially regarding whether the chicken widely eaten at fast-food restaurants and purchased from supermarkets might be genetically modified.

We went behind the scenes at Kenchic’s modern processing facility to trace the path of chickens and various final products, from hatching through to halal-certified slaughtering, inspection, packaging, and finally into cold storage.

The establishment provides for several of Kenya’s largest corporations, such as KFC, key grocery store networks, dining establishments, and homes throughout the nation.

Kenchic chicken farms

The process starts at Kenchic’s hatchery, where numerous chicks emerge in germ-free surroundings. These newly hatched chicks are swiftly moved to Kenchic farms, where they grow up in meticulously regulated settings; meanwhile, some are distributed to poultry farmers.

Percy Musyoki, who serves as the Quality Assurance Manager, during the factory tour mentioned that the firm guarantees chickens are bred under secure and wholesome environments. He also pointed out that despite having a significant demand, the company refrains from purchasing additional chickens from external sources.

“To ensure the chickens we process are safe and free of pesticides or diseases, we maintain specific safety standards. As we can’t verify the raising conditions of externally sourced chickens, we refrain from purchasing them from external sources,” Musyoki clarified.

Over approximately 33 days, the broilers receive a meticulously formulated diet to promote healthy development. The conditions such as temperature, feeding, watering, and lighting are continuously observed to uphold welfare standards.

From Kenchic farms to the Kenchic processing facility

When the broilers achieve their target weight, they are transferred to Kenchic’s meat processing facility. At this stage, the chickens move through an entirely mechanized slaughtering and processing system.

Musyoki pointed out that their procedure has Halal certification, which is a crucial criterion for numerous Kenyan customers and overseas clients.

“We have Halal certification. Once the chickens arrive from the farms, they are placed in a temperature-controlled holding area equipped with blue lights, which are suggested to enhance their comfort and prevent them from getting frightened,” explained Musyoki.

The killing procedure is both gentle and quick, succeeded by a rigorous 45-minute automatic cleansing phase that eliminates all feathers and entrails. Throughout the entire process, limited human involvement guarantees stringent levels of cleanliness and security.

Is the meat suitable for humans to eat?

Once cleaned, the chickens undergo health checks performed by a resident meat inspector affiliated with the Directorate of Veterinary Services (DVS). This organization functions within the Ministry of Agriculture and Livestock Development.

DVS officials examine the inner organs of each chicken and verify that only those deemed fit for human consumption move forward in the processing stage.

The DVS implements the Meat Control Act, overseeing slaughterhouse activities and ensuring meat safety through ante- and post-mortem inspections. The chicken can only advance to the subsequent phase following this approval and certification process.

Kenchic’s meat processing and packaging facility

After inspection, the chicken is categorized by weight and prepared as per customer requests. The chicken is

Part of the meat is directed towards value-added processing, transforming it into items such as chicken smokies, sausages, and various ready-to-cook or ready-to-eat goods. These products are widely favored throughout Kenya, particularly among customers at small food stalls and street-side sellers.

Once packaged, all items are transferred to sanitized cold storage areas kept at -8°C to maintain their freshness. For customers like KFC and prominent supermarkets that opt for frozen goods, the poultry is sent to blast freezers. These specialized equipment freeze the chicken at very low temperatures over a period of 16 hours, ensuring complete freezing throughout.

Cold chain management ensures the meat stays both secure and top-notch from transport all the way through to delivery to clients such as individual consumers along with major eateries and retail chains.

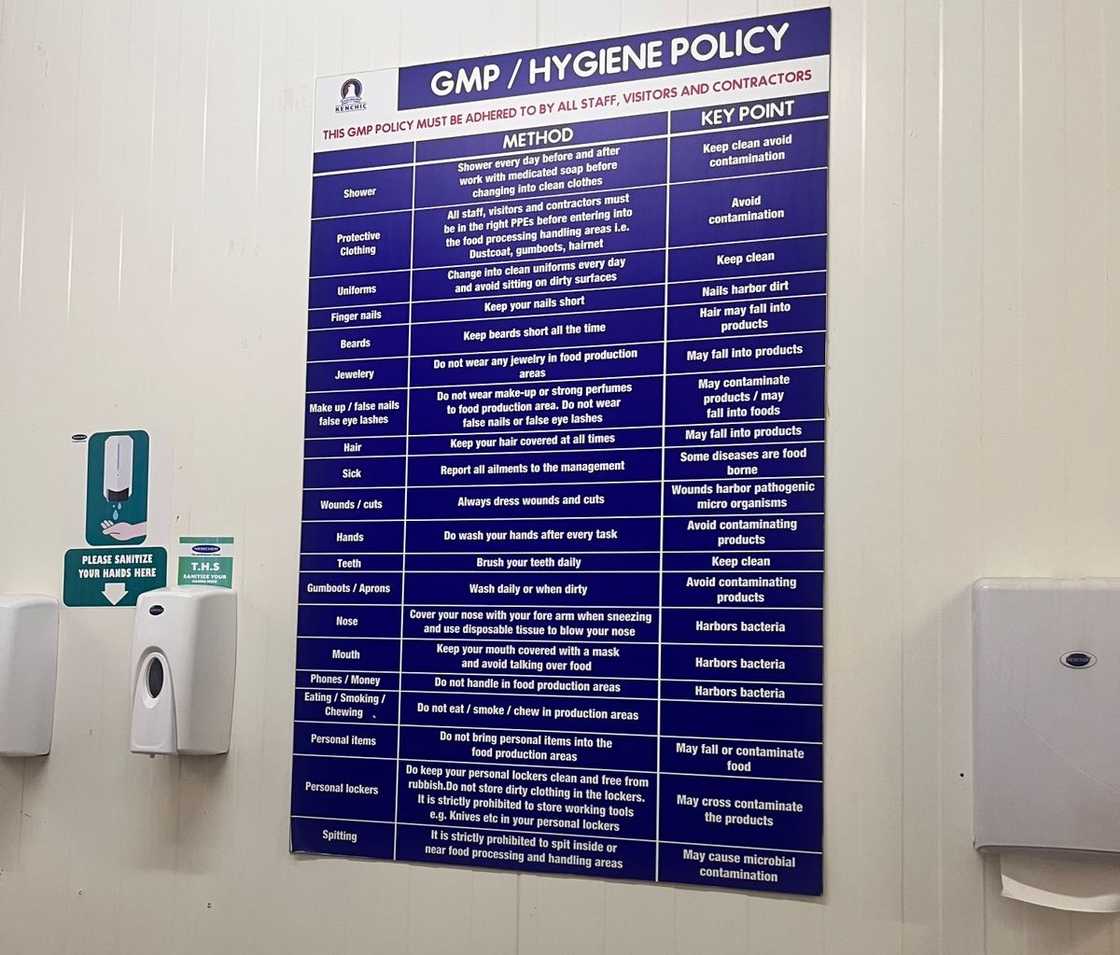

Musyoki emphasized that maintaining cleanliness is the top priority at the factory, which also applies to the employees who must follow a series of steps before entering the facility. Here’s an excerpt from the hygiene policy implemented at the plant:

The quality assurance officer mentioned that the manufacturing departments in the plant operate solely during the daytime shift.

Throughout the nightly shift, a different team of employees powers down the machinery and thoroughly cleans the whole facility, even wiping down the walls. They also perform tests to confirm that no Salmonella bacteria or other microbes remain on either the surfaces or equipment used for processing. These tasks are carried out daily without fail.

Water supply, energy resources, and waste handling

Like numerous other processing facilities, the factory necessitates a continuous supply of water for uninterrupted operation throughout the day and night.

The Kenchic plant is conveniently situated near the Chania River. Water is sourced from this river and undergoes a purification procedure prior to being utilized for consumption, sanitation, and various operations within the facility.

Musyoki mentioned that on the opposite side of the factory lies the Ol Donyo Sabuk River. He further clarified that the company operates an additional wastewater treatment facility designed to remove all solids from the water prior to releasing it into the river. This process adheres to the regulations set forth by the National Environmental Management Authority (NEMA).

The factory obtains its electricity from the national grid; nonetheless, to reduce energy expenses, it also features a solar power plant.

Four decades ago, Kenchic was established with the aim of offering an inexpensive and accessible protein option for Kenyan citizens. Today, it stands as one of the leading providers of chicks to local farmers, along with poultry meat and various other meat products throughout Kenya.