The Decline of Forest Cover in Kalangala

Kalangala, a district that once boasted a forest cover of 57 percent in 1954, now has only 22 percent remaining. This drastic decline has left just 8,700 hectares of forest reserves. According to district environment reports, the main causes of deforestation include rice farming, oil palm cultivation, charcoal burning, timber cutting, and human settlement. The loss of forests has led to significant environmental consequences, including the release of about 45,000 tonnes of carbon dioxide into the atmosphere between 2000 and 2024.

Oil Palm as an Unexpected Ally

While oil palm plantations were once blamed for the loss of forests in Kalangala, they are now playing an unexpected role in protecting the remaining forest cover. Ms Asher Birabwa Kirunda Kivejinja, a social worker with Ragu Farms Ssese in Lutoboka Village, has initiated a project to create charcoal briquettes using oil palm fronds. This initiative was sparked by the need for a cleaner and more sustainable alternative to traditional charcoal after waterspouts hit Buggala Island in May, leaving many without access to firewood.

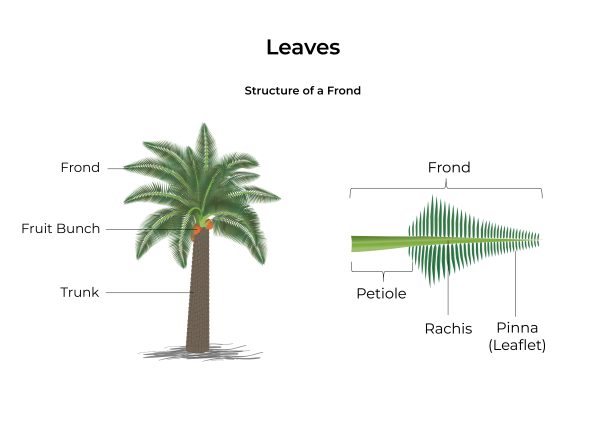

The Potential of Oil Palm Fronds

Kalangala is home to approximately 12,000 hectares of oil palm plantations, with around 1.68 million oil palm trees. Each tree produces 20 to 25 fronds annually, and each frond can yield about 5 kilograms of charcoal. This potential is immense, with estimates suggesting that the district’s oil palm plantations could produce over 33.6 million fronds each year, enough to make 168,000 tonnes of charcoal briquettes.

Ms Birabwa uses a homemade kiln and a hand-operated press to produce 400 kilograms of briquettes for the community monthly, and 600 kilograms for the outside market. A five-kilogram bag of frond briquettes costs Shs5,000, which is cheaper than regular charcoal that costs around Shs7,000. These briquettes burn cleanly, producing no smoke and a blue flame, making them safer for daily use, especially for women and children.

Market Adoption and Challenges

Individual homes and institutions, including schools outside Kalangala, have started using the briquettes. Banga Project, a community-based group supporting vulnerable children, is among the local users, purchasing up to 200 kilograms of briquettes at the start of each school term. However, no oil palm farmers in the district have begun selling fronds, although some willing farmers provide them for free to Ragu Farms Ssese.

Sustainability and Crop Health

Some farmers have raised concerns about whether large-scale harvesting of fronds could harm the palm crop. Experts, however, argue that this practice is sustainable. Mr David Balironda, managing director of Ssese Oil Palm Growers Cooperative, explains that mature oil palm trees have over 45 fronds, and only old or damaged ones are removed. This process does not affect the fruit or the plant’s health. Turning pruned fronds into charcoal is both environmentally and economically beneficial, potentially creating a second income stream for farmers.

Scaling Up the Initiative

Despite the promising potential, scaling up the project presents challenges. Ms Birabwa emphasizes the need for machinery, training, and government support. With more briquette-making machines, the project could transform how the island cooks and help preserve its forests. Mr Joseph Byaruhanga, the Kalangala District environment officer, remains optimistic about the impact of using oil palm fronds for briquettes on reducing deforestation but highlights the need to make the product more appealing and accessible to households.

Resident Experiences and Future Prospects

Not all residents are convinced of the benefits. Ms Solomy Kasirye, a resident of Kalangala Town Council, shares her negative experience with briquettes, noting that they burned faster than normal charcoal and that she still needs to buy a new sack every month. She suggests that for briquettes to replace traditional charcoal, they must be durable, affordable, and of high quality.

Other countries, such as Malaysia, have already advanced in utilizing oil palm fronds for various purposes, including charcoal briquettes, animal feed, compost, and even building materials. Malaysia produces over 40 million metric tonnes of dry frond waste annually, highlighting the potential for similar initiatives elsewhere.