Apera Forge: Revolutionizing 4D Vision-Guided Robotics with AI

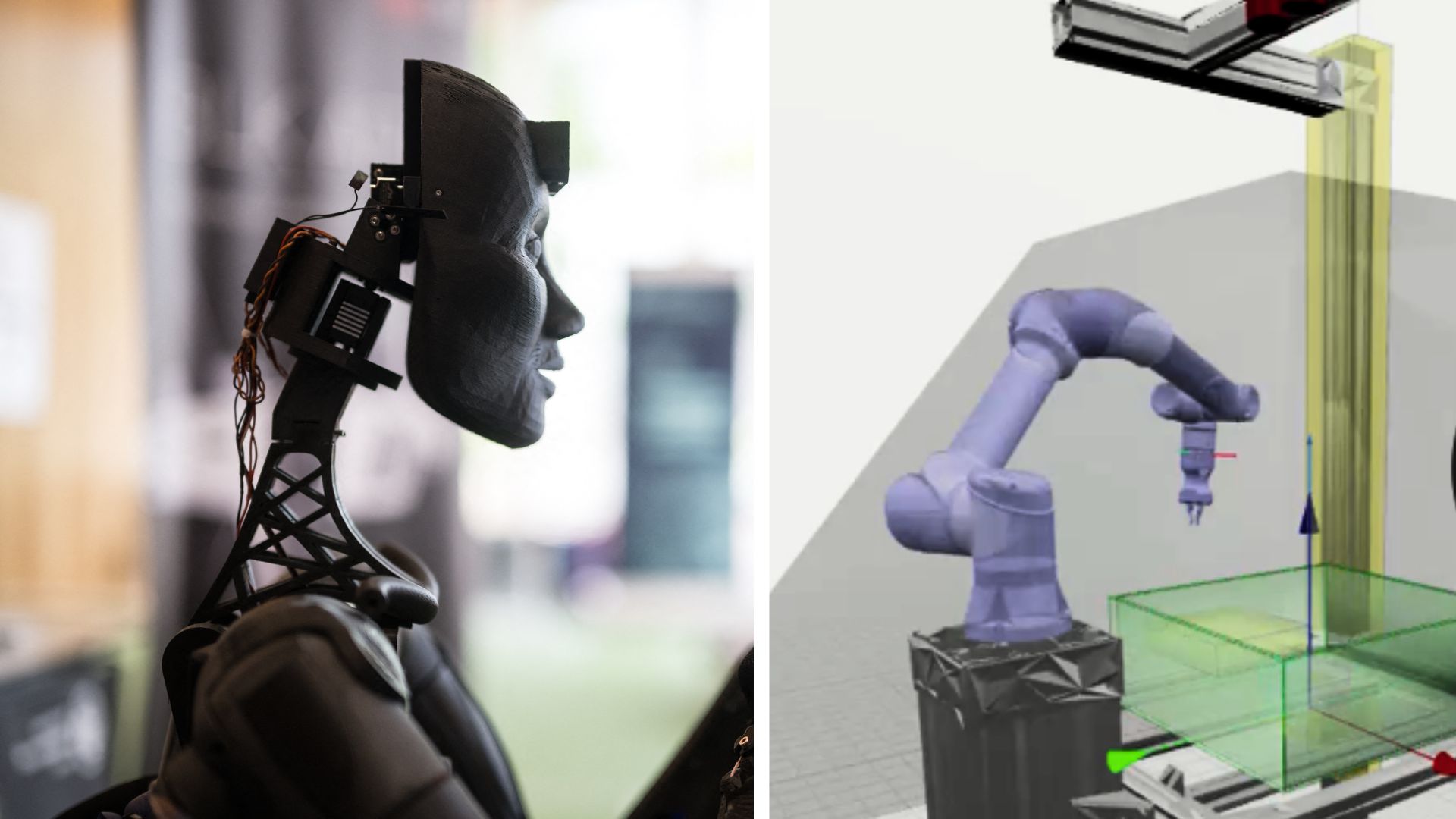

A Canadian company has introduced a groundbreaking web-based design and AI training studio that simplifies complex 4D vision-guided robotic projects. Known as Apera Forge, this browser-based platform eliminates the need for hardware, offering an advanced AI vision design studio accessible through any modern web browser.

The system’s latest features include support for advanced robotic cell design, end-of-arm-tooling (EOAT)-mounted camera configurations, and full simulation and training for de-racking applications. This makes Apera Forge a powerful tool for streamlining 4D vision-guided robotics automation projects.

Reducing Time and Risk in Development

Developed by Apera, the system is powered by artificial intelligence and significantly reduces the time and risks involved in developing vision-guided robotic cells. It is particularly useful for tasks such as bin picking, material handling, and now de-racking. According to the company, industrial manufacturers can achieve in hours what once took weeks or even months, dramatically shortening implementation time while ensuring the success of vision-guided robotic (VGR) automation projects.

Users can start by simulating their application, including parts, gripper, robot, and cell environment—this process takes minutes rather than days. Then, Forge trains an AI neural network through a million digital cycles to achieve over 99.9% reliability in recognizing objects and performing tasks. The result is a complete vision program ready for deployment on-site within 24-48 hours.

Enhanced Flexibility in Cell Design

Apera Forge helps users build and validate their bin picking and de-racking cells and train their AI vision program in a simulation environment. This approach eliminates the need to invest in hardware upfront, giving users confidence that their robotic cell will perform to specifications.

With the latest upgrade, Forge now supports advanced cell design with greater flexibility. Users can tune camera placement, bin positioning, and multiple obstacles to better match real-world layouts and improve simulation results. This enhanced capability allows for more accurate and efficient planning of robotic systems.

Full Simulation and AI Training

Forge now supports full simulation and AI-powered training for de-racking applications. Users can define structured part layouts, simulate picks, and train vision models for faster deployments. The system offers complete self-serve training and validation inside Forge, making it easier for integrators and industrial manufacturers to manage their projects independently.

This feature is specifically designed for racked parts, where consistent spacing, orientation, and rack structure are critical for effective part recognition and picking. Users can train robust AI vision models directly within Forge without contacting Apera engineers, saving significant time and resources.

Support for EOAT Mount Configurations

In addition to fixed mount (eye-to-hand) configurations, Apera Forge now supports EOAT mount (eye-in-hand) vision configurations. This allows users to design and validate setups where cameras are mounted directly on the robot’s end-of-arm tooling (EOAT).

The system can visually determine ideal camera placement on end-of-arm tooling by previewing camera views, ensuring clear and unobstructed vision of parts. This functionality enhances the accuracy and efficiency of robotic operations.

Integrated Autopilot Obstacles

Apera Forge also supports integrated autopilot obstacles for enhanced robot navigation and collision avoidance in simulations. Users can import their complete Vue cell setup, including bins, search regions, obstacles, tables, and calibrated cameras. This integration ensures that robotic systems can navigate complex environments safely and efficiently.

Overall, Apera Forge represents a significant advancement in the field of 4D vision-guided robotics. By leveraging AI and providing a comprehensive simulation environment, the platform empowers industrial manufacturers to streamline their automation projects, reduce development time, and improve the reliability of their robotic systems.